“Achieving the ‘green’ label is no easy feat.”

The European energy crisis triggered a frenzy of activity around hydrogen. Three years on, some major hurdles remain to enable hydrogen to scale in Europe, particularly relating to policy support and costs.

Some well backed projects are gradually making FID, but a key challenge to achieving this is defining a viable ‘green power’ sourcing strategy for electrolysers. In today’s article we focus on that challenge.

Green hydrogen production: key criteria

In June 2023, the European Commission formally adopted two delegated acts establishing detailed rules for defining renewable hydrogen under the EU’s Renewable Fuels of Non-Biological Origin (RFNBOs) framework. These acts ensure that hydrogen labelled as “green” is genuinely produced using renewable electricity, aligning with the EU’s ambitious decarbonisation goals.

To be considered green, hydrogen production must satisfy three main criteria:

- Additionality: Electrolysers must use renewable power that would not otherwise have been generated. This ensures the electrolyser energy demand doesn’t cannibalize existing renewable capacity.

- Temporality: Hydrogen production must be temporally aligned with renewable generation. While monthly alignment suffices until 2030, hourly alignment will be required thereafter, tightening the operational constraints.

- Geographical Alignment: Electrolysers and renewable assets must be co-located or within interconnected bidding zones to ensure direct use of green energy.

These rules aim to guarantee that green hydrogen truly contributes to emissions reductions but also add complexity for developers and operators.

Sourcing configurations and challenges

There are four main options for sourcing electricity to produce green hydrogen, each with distinct requirements and implications. Each option presents unique challenges in scaling production and integrating hydrogen into the power system.

Table 1: Green Hydrogen sourcing configurations

We will now look at each of these sourcing options in detail to evaluate the challenges associated with each method.

1. Grid Power

Sourcing electricity directly from the grid offers flexibility but raises significant hurdles under the EU’s rules. Hydrogen can only qualify as green if:

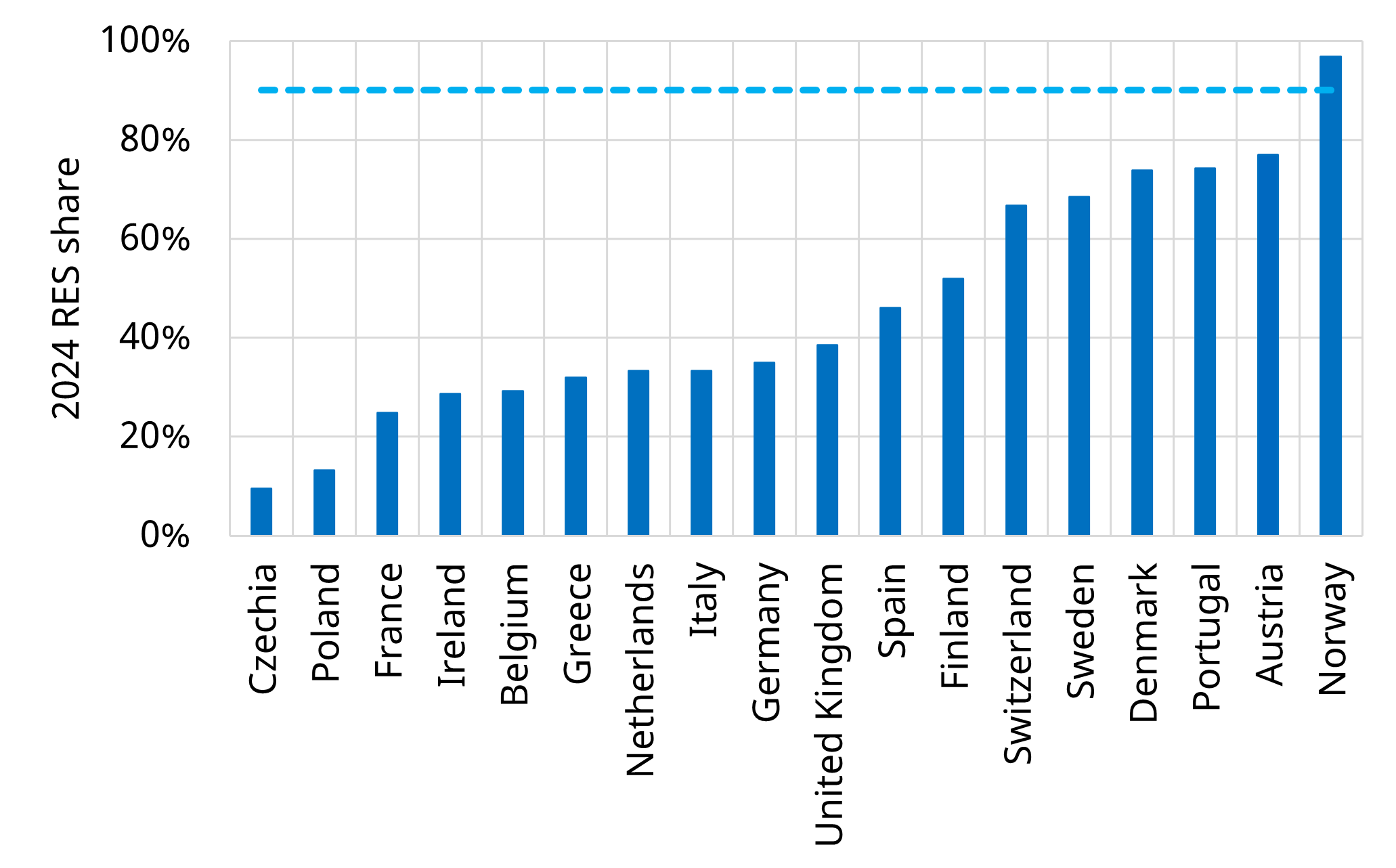

- The electrolyser operates in a region where renewable electricity exceeded 90% of the mix in the previous year, with compliance valid for five years.

- Alternatively, the electrolyser uses curtailed renewable power, requiring evidence from the grid operator.

This pathway relies heavily on regions with high renewable penetration, such as Scandinavia, or areas with significant curtailment. As Chart 1 below shows, other than in Norway, renewable generation levels are not yet sufficient to enable green hydrogen sourcing via the first criteria.

2. Co-located renewable assets

Electrolysers directly paired with renewable energy sources, such as solar or wind farms, inherently meet geographical and temporal requirements. However, additionality requires that the renewable asset be commissioned within 36 months of the electrolyser.

While this setup provides the cleanest and simplest route to green hydrogen, its operational feasibility is constrained by the variability of renewable output. Electrolysers in this configuration often sit idle during low generation periods, creating inefficiencies. Without robust hydrogen storage or pipeline infrastructure, this approach struggles to meet the consistent supply demanded by industrial applications.

3. Power Purchase Agreements (PPAs)

PPAs offer a middle ground, enabling developers to source electricity from off-site renewable projects. For hydrogen to qualify as green:

- The renewable asset must be unsubsidized and newly built, or the electrolyser must have been operational before 2028.

- Temporal and geographical criteria still apply, becoming stricter with hourly alignment post-2030.

The reliance on PPAs introduces complexity in managing electricity flows and ensuring compliance. Furthermore, PPAs depend on a mature market for renewable projects and a supportive regulatory framework, both of which vary significantly across the EU.

4. Hybrid Models

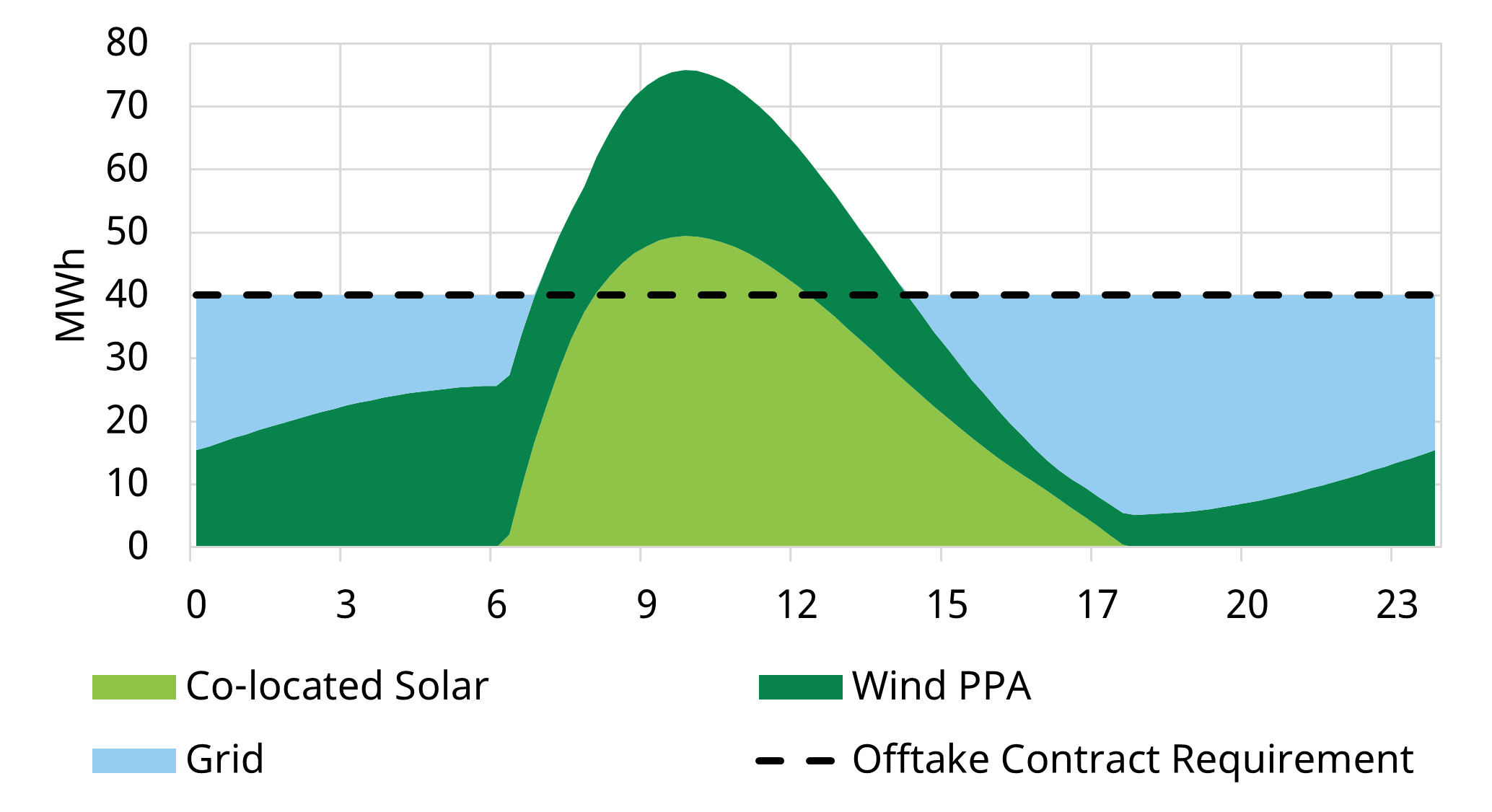

Many projects are exploring hybrid configurations that combine co-located renewables, PPAs, and grid electricity. For example, an electrolyser paired with a solar farm might draw on grid power at night. In these cases, the applicable criteria depend on the electricity source used at any given time.

This hybrid approach offers flexibility but complicates emissions accounting. Under EU rules, lifecycle greenhouse gas (GHG) emissions are averaged across all hydrogen produced. This means that even partial reliance on fossil-fuelled grid power could disqualify the output from being considered green.

Building a bankable project

Defining a viable power sourcing strategy (across the options above) has been a key focus of our work with clients building a hydrogen investment case.

Power sourcing is critical because:

- Compliance with sourcing guidelines enables access to policy support

- Sourcing strategy is an important driver of electrolyser production cost structure.

Getting sourcing strategy right early in the project is important because of its knock-on impacts on optimal project configuration, cost & offtake structure.

We set out in more detail here how to approach the analysis of hydrogen electrolyser project sourcing strategy & revenue stack.

Feel free to reach out to Lucienne Hill Smith (lucienne.hill.smith@timera-energy.com) if you would like more details.